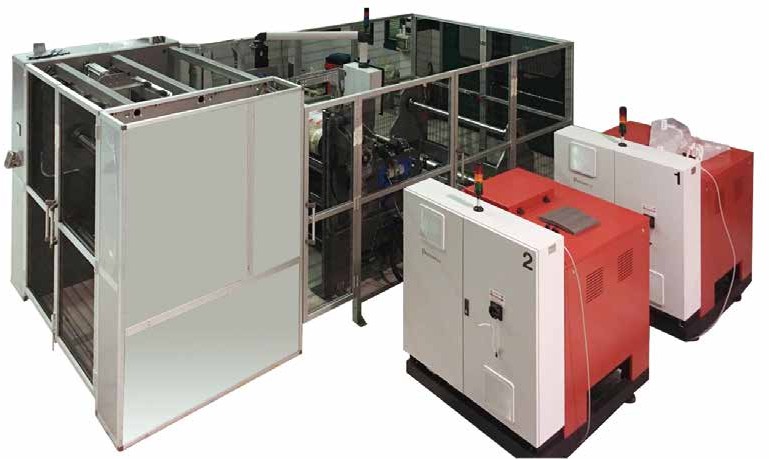

LAMINATING MACHINE FOR THE PRODUCTION OF LAMINATED COATED, SILICONE PAPER WITH NON-WOVEN AND SEVERAL PRODUCTS SUCH AS FILM, ELASTIC FABRICS. COATING SYSTEM BY A SLOT DIE HEAD.

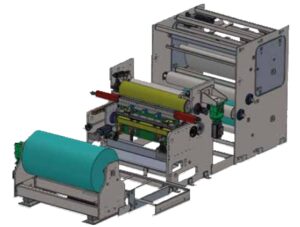

COATING HEAD GROUP

- Top driven laminating AISI 304 cylinder diam. 240 mm aprox.

- Coating roll diam. 280 mm in silicon rubber and cooled with water

- Height adjustment by hand wheel

- Massima temperatura di Iavoro 240°C carico

- Adjustment mechanic driven jack

- Movement precision 0,01mm

MELTING TANKS

- 1 or 2 Melting tanks for PSA (pressure adhesive) each one having:

- Teflon tank with 65 l capacity

- Fusing capacità 80- 100 Kg/h mcx max

- Temperatura massima di esercizio: 210°C

- N. 2 independent temperature zones

- Feeding gear pump controlled by inverter. Max capacity 40 l/h

- Temperature control of feeding pipe

- Automatic feeding adjustment based on production speed

SILICON PAPER FEEDING GROUP

• Axial unwinding for single roll

• Roll diam. 120-650 mm

• Driven system, tension controlled by load cell

NON WOVEN FEEDING GROUP

• Axial unwinding for single roll located on the back of machine

• Roll diam. 120-650 mm

• Driven system and tension controlled by load cell

• Driven centring device for automatic alignment

• Rubbered spreading cylinder with manual angle adjustment

WINDING GROUP FOR LAMINATED PRODUCT

- • Axial winding for single roll located on the back of machine

- • Roll diam. 12O-8OO mm

- • Rotation on both side

Click the icon to download catalogue