SLITTING MACHINE FOR ALUMINIUM-COPPER AND LAMINATED BATTERY

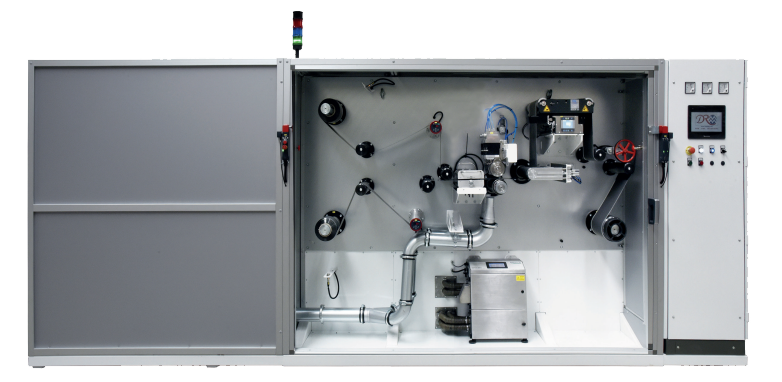

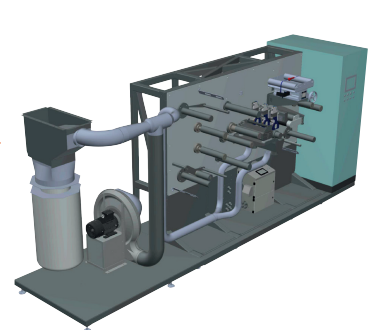

COMPACT SLITTING MACHINE SUITABLE FOR THE CONTINUOUS CUT OF ALU- MINUM-COPPER AND LAMINATED, INCLUDING EDGE TRIMMING AND COL- LECTION, WITH SUCTION DEVICE FOR THE MICRODUSTS.

THE REWINDING AND SLITTING MACHINE IS DESIGNED TO SLIT STRIPS WITH MORE CUTTING UNITS, AND EDGES REMOVAL. A SAFETY ENCLOSURE CONNECTED TO AN EXTERNAL ASPIRATION DEVICE LIMITS RISKS OF DISSEMI- NATION OF SMALL PARTICLES AND ENSURES A MECHANI- CAL PROTECTION OF THE OPERATOR.

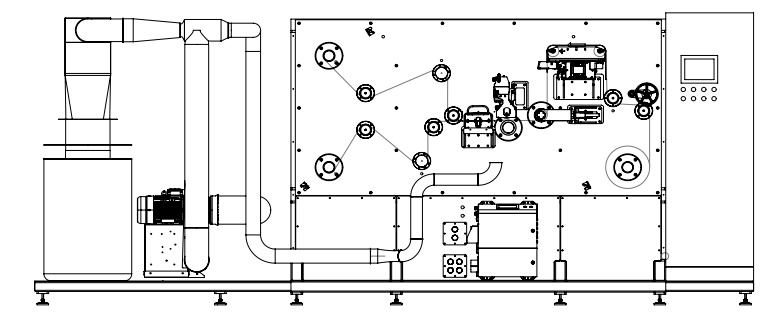

MAIN COMPONENTS

Axial single unwinder on expandable shaft

Slitting unit

Dust suction unit in the cutting area

Deionizing bars

Double axial rewinder on expandable shaft

Very compact structure, mono-block

Precision worked Frames painted

Closed enclosure connected to an aspiration system

TECHNICAL DETAILS OF MAIN DEVICES AND MOTORISATION

Mechanical speed adjustable from 0 to 100 m/min (real speed of production depending on the kinds of film/fabric and regularity of the density of the bobbin).

Motorization Dy “vectorial inverter”.

The HMI provides control of the main machine functions and settings as well as diagnostic and alarms pages with our dedicated software.

Electrical main supply 3PH+N+E 400Vac 50Hz (if there are not other specifications).

Auxiliary circuits voltage 230Vac - 110Vac - 24Vdc.

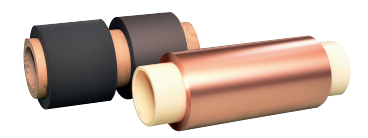

Product to be processed:

Cu thickness 6-20 um

Al thickness 8-20 um

Coated thickness 50-200 um

TECHNICAL DETAILS

Max working web width 400 mm

Min working web width 250 mm

Max diam. mother roll unwinder 320 mm

Max unwinding reel weight 200 kg

Unwinder cores 3” or 6”

Max weight on individual winding shaft 200 Kg

Max diam. rolls wound 320 mm

Rewinder core 3”

Minimum slit width 25 mm

Slitting method Scissor

Safety rules EN/CE

Download