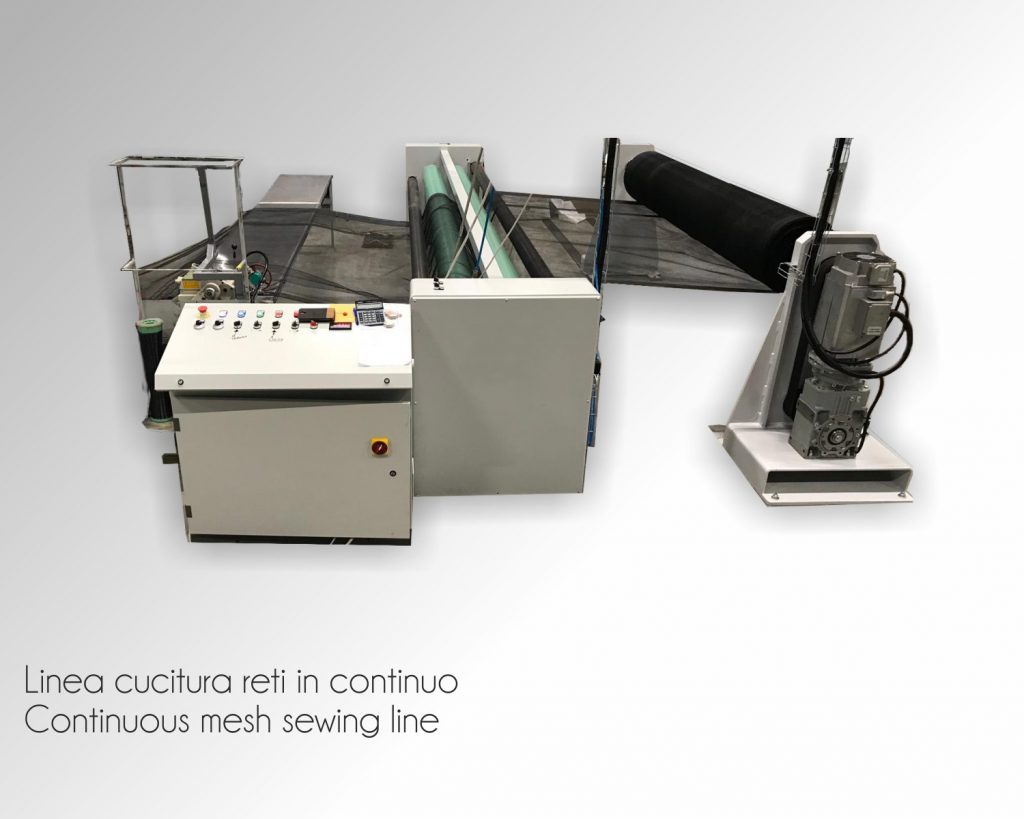

SEWING BENCH

- Table for help sewing operation.

- Sewing machine with encoder for synchronisation with mainmotorisation.

MAIN MOTORISATION

- Double motorized cylinder for pull the 2 layers of net together

- Synchronisation with winding device and sewing speed.

TECHNICAL CHARACERISTICS

- VECTORIAL INVERTER motorisation with automatic reading of diameter.

- Full controlled tension and adjustable.

- Maximum compaction of roll wound for reduction of diameter.

Continuous mesh sewing line

Products and process details:

- Anti-hail net.

- Max. working width 5.800mm

- Cylinder width 6.000mm

- Max.speed 0-60 m/min

Installation detail:

- Power installed 7kw 3 x 400 VAC + N+T circa 5%

- Motorisation by VECTORIAL INVERTER with automatic reading of the diameter of roll.

UNWINDING DEVICE

- Double unwinding device with lateral supports. Pneumatic lift up device from ground to unwinding position.

- Unwinding operation by a pneumatic device with braking system controlled through laser reading the diameter of roll.

WINDING DEVICE

- Axial motorized winding device,synchronized with the main motrisation

- Lateral chucks for fit expandable shaft

- N°1 lateral support with installed the motoreductor

- N°1 lateral support sliding on the ground to be adapted to the different sizes of expandable shaft.

- Foot pedal for manual operation of winding to permit to turn the roll for stretch film wrapping.